Introduction

The Link VQ35DE Trigger Offset is a well-regarded 3.5L V6 engine produced by Nissan. It powers several Nissan and Infiniti models such as the 350Z, Maxima, Altima, Murano, Pathfinder, and the Infiniti G35. One of the fundamental components of this engine is its crankshaft position sensor (CKP), which relies on a trigger wheel (also known as a reluctor wheel) to send signals to the ECU to track the engine’s timing and position. A critical part of this process is understanding the concept of trigger offset and its effect on engine performance.

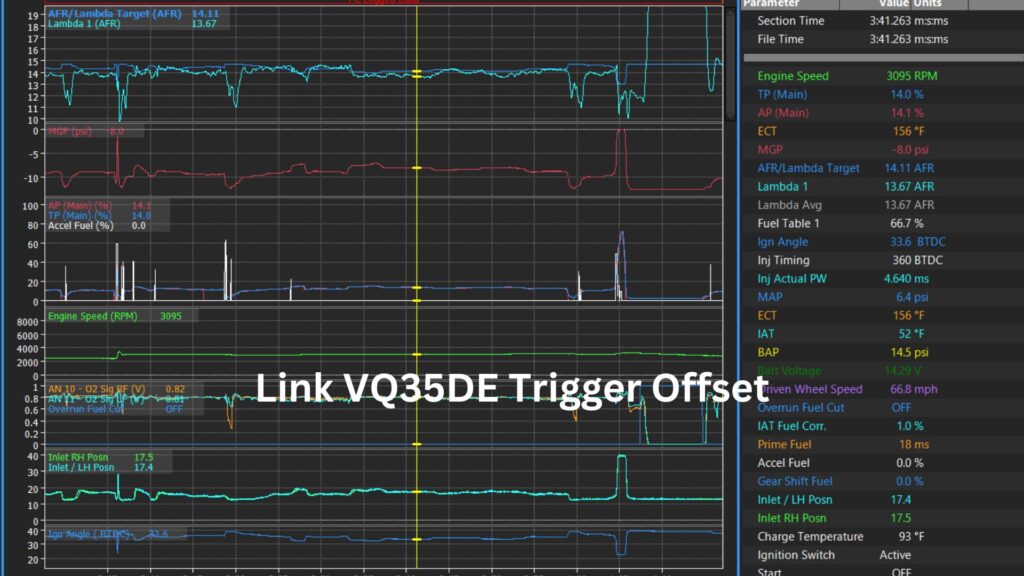

In this article, we’ll delve into the concept of trigger offset for the VQ35DE engine, its importance, how to adjust it for improved engine performance, and the role it plays in optimizing ignition timing. This guide is especially useful for those looking to modify their VQ35DE engine or integrate it with aftermarket engine management systems.

What is the Link VQ35DE Trigger Offset in the VQ35DE Engine?

The trigger offset refers to the angular difference between the actual position of the crankshaft and the reference point used by the ECU to calculate ignition timing. For the VQ35DE engine, the trigger wheel (also known as the reluctor wheel) plays an integral role in sending signals to the crankshaft position sensor (CKP) to communicate the crankshaft’s rotation to the ECU. This information is critical for the engine’s ignition system to determine the correct timing for each cylinder.

Crankshaft Position Sensor (CKP)

The crankshaft position sensor detects the position of the crankshaft via a rotating reluctor wheel, which features a series of teeth, with specific ones missing to serve as reference points. The sensor counts the teeth as they pass, and the missing teeth provide a clear signal that helps the Link VQ35DE Trigger Offset pinpoint the crankshaft’s exact position in relation to the engine’s power stroke.

The VQ35DE uses a 36-2 tooth reluctor wheel—36 teeth with 2 missing. These two missing teeth give the ECU an important reference signal, and the rest of the teeth are used for determining the crankshaft’s RPM.

Trigger Offset in the VQ35DE

The trigger offset refers to the angle difference between the position of the missing teeth on the reluctor wheel and the ECU’s desired reference point. This angle can affect ignition timing, which in turn influences engine performance, fuel efficiency, and smooth operation. The trigger offset is essential because the ECU relies on this reference to know when to fire each cylinder’s spark plug, ensuring combustion occurs at the optimal moment.

Also read: Florence Noise Serum Bank

Factory Trigger Offset for the VQ35DE Engine

Out of the factory, the VQ35DE engine comes with a predefined Link VQ35DE Trigger Offset value set by Nissan. This default value is usually designed for factory components and stock ignition timing settings. Understanding this factory offset is important when tuning the engine or when troubleshooting issues related to ignition timing.

Stock Trigger Offset Value

The factory default trigger offset for the VQ35DE is typically around 325° to 355° Before Top Dead Center (BTDC). The BTDC refers to the crankshaft’s position relative to the Top Dead Center (TDC) of the cylinder’s compression stroke. This means the crankshaft’s position is slightly before the piston reaches the top of its travel on the compression stroke.

Why This Matters

The trigger offset value determines the timing at which the ECU triggers the spark plug. If the offset is too high or too low, it can throw off the ignition timing, leading to misfires, poor fuel economy, and even engine damage. Therefore, setting this value accurately is crucial for the engine to run efficiently.

Adjusting the Link VQ35DE Trigger Offset for Aftermarket ECUs

For those who are upgrading or modifying their VQ35DE engine with aftermarket engine management systems such as Haltech, AEM Infinity, or Link ECU, it’s essential to adjust the trigger offset to ensure that the ignition timing is still accurate. A standalone ECU often allows for more precise control over ignition timing, and the trigger offset may need to be recalibrated for the engine’s new setup.

Why Aftermarket ECUs Require Adjustments

Aftermarket ECUs usually allow for greater flexibility and customizability. When switching to one of these systems, the Link VQ35DE Trigger Offset might need to be modified due to differences in how the aftermarket systems interpret the crankshaft position sensor signal.

The trigger offset may need to be adjusted if:

- The engine has been modified with higher compression ratios or turbocharging.

- Fuel injectors or the ignition system have been upgraded.

- The sensor types or configurations have changed.

Adjusting the offset is essential for avoiding issues like misfires or knocking, which can occur if the timing is not correctly synced with the engine’s mechanical operation.

How to Set the Trigger Offset for Aftermarket ECUs

The process of adjusting the trigger offset involves using a timing light to check the ignition timing and then modifying the value in the ECU’s software until the correct timing is achieved. Here’s a general process:

Step 1: Set the ECU to Fixed Ignition Timing

First, ensure the Link VQ35DE Trigger Offset is set to a fixed ignition timing value (for example, 10° BTDC). This will allow the timing light to be accurate without any ECU adjustments occurring during the process.

Step 2: Connect the Timing Light

The timing light should be connected to the first cylinder’s ignition coil or spark plug wire. The timing light will flash each time the ignition system fires, allowing you to observe the timing mark on the crankshaft pulley or flywheel.

Step 3: Verify Base Timing

With the engine running, use the timing light to verify the ignition timing. If the timing light shows that the ignition timing is too advanced or too retarded, the trigger offset value needs to be adjusted in the ECU software.

Step 4: Adjust the Trigger Offset

Using the ECU’s tuning software, adjust the Link VQ35DE Trigger Offset until the timing light shows the correct base timing value. In most cases, this will be around 10° BTDC, but it may vary depending on your specific engine setup.

Step 5: Test and Refine

Once the correct trigger offset is set, test the engine under various conditions (idle, partial throttle, full throttle) to ensure that the ignition timing is accurate across the RPM range. Fine-tune the settings as needed.

Common Trigger Offset Values for Aftermarket ECUs

Different aftermarket ECUs may have slightly different default values for Link VQ35DE Trigger Offset. It’s important to consult the ECU’s manual for recommended settings, but here are typical values:

Haltech ECU

- Trigger Offset: 330° – 350° BTDC

- Haltech ECUs often have a range of acceptable offset values. Fine-tuning may be necessary depending on the model year of the VQ35DE engine and the type of sensor used.

AEM Infinity ECU

- Trigger Offset: 335° – 345° BTDC

- The AEM Infinity ECU typically falls within this range, although adjustments may be required for specific engine builds or modifications.

Link ECU

- Trigger Offset: 340° – 355° BTDC

- Link ECUs are known for their precision, and this range is typically suitable for most VQ35DE builds, especially those with high-performance modifications.

Common Issues Caused by Incorrect Link VQ35DE Trigger Offset

If the trigger offset is set incorrectly, several issues can arise, some of which can seriously affect the engine’s performance and longevity. These include:

1. Engine Misfires

Misfires occur when the spark plug is fired at the wrong time in the engine’s cycle. If the trigger offset is too far advanced or retarded, the ECU will incorrectly fire the spark plug before or after the cylinder reaches the optimal combustion point, causing incomplete combustion and potential damage.

2. Poor Fuel Economy

If the timing is off, the engine may burn more fuel than necessary to maintain performance, leading to poor fuel efficiency. This is often a result of incorrect Link VQ35DE Trigger Offset, as the engine is running outside of its optimal power band.

3. Engine Knock (Detonation)

Engine knock is caused by premature combustion, typically when ignition timing is too advanced. Incorrect trigger offset can lead to knock, especially in high-compression engines or forced induction setups like turbocharged or supercharged VQ35DE engines. Engine knock can result in severe damage to pistons, valves, and other components.

4. No Start Condition

If the trigger offset is set too far out of range, the engine may fail to start altogether. This is because the ECU will be triggering the spark plugs at an incorrect time, and the engine may not achieve the correct compression or ignition cycle to fire the cylinders.

Conclusion

The Link VQ35DE Trigger Offset is a crucial factor in ensuring proper engine timing and performance for the VQ35DE engine. Understanding how it works, its factory setting, and how to adjust it for aftermarket engine management systems will help ensure that the engine runs smoothly and efficiently.

Whether you are upgrading your ECU, tuning your VQ35DE for performance, or simply ensuring that the engine is operating correctly, it’s essential to check and adjust the trigger offset to avoid performance issues such as misfires, engine knock, or poor fuel economy. By following the procedures outlined in this guide, you can optimize your engine’s performance and ensure that the VQ35DE runs at its best.