A wheel bearing is a crucial component of a vehicle’s suspension system. It allows the wheels to rotate smoothly while supporting the vehicle’s weight and reducing friction. However, when a wheel bearing starts to fail, it can produce various noises that indicate a problem. These noises often serve as early warning signs, alerting drivers to potential safety hazards.

In this comprehensive guide, we’ll explore the causes, symptoms, diagnosis, and solutions for wheel bearing noise. By the end of this article, you’ll have a detailed understanding of how to identify and fix wheel bearing issues before they lead to more significant problems.

What is a wheel bearing noise?

A wheel bearing is a set of steel balls or rollers enclosed in a metal ring (race). It sits inside the wheel hub and allows the wheel to spin with minimal friction.

Wheel bearings come in different types, including:

- Ball Bearings – Most common, capable of handling radial and axial loads.

- Roller Bearings – Cylindrical rollers that reduce friction effectively.

- Tapered Roller Bearings – Designed for handling both thrust and radial forces, commonly used in trucks and larger vehicles.

Since wheel bearing noise are subject to constant stress, they require lubrication. Over time, wear and tear or lack of lubrication can lead to wheel bearing failure, resulting in noticeable noise.

Common Causes of Wheel Bearing

There are several reasons why a wheel bearing may start making noise. Below are the most common causes:

1. Wear and Tear wheel bearing

Wheel bearings naturally degrade over time due to continuous friction and load-bearing stress. The more miles a vehicle accumulates, the more likely it is for the wheel bearings to wear out and produce noise.

2. Lack of Lubrication

Bearings need proper lubrication to function smoothly. If the grease inside the bearing wears out or leaks, the metal parts will grind against each other, leading to noise and premature failure.

3. Water or Dirt Contamination

Wheel bearings are sealed to prevent dirt and moisture from entering. However, if the seal gets damaged, contaminants can enter the bearing, causing corrosion and noise.

4. Poor Road Conditions

Driving over potholes, rough roads, or speed bumps at high speeds can damage wheel bearings. Repeated impacts put excessive strain on the bearings, leading to early failure.

5. Improper Installation

Incorrectly installed wheel bearings can wear out faster. Over-tightening or under-tightening can affect the bearing’s lifespan and lead to premature noise issues.

Previous article; Where to watch Real Madrid vs C.F. Pachuca Live Streaming, TV Channels, and Match Details

6. Vehicle Modifications

Aftermarket wheel bearing noise, spacers, or oversized tires can change the vehicle’s load distribution, putting additional stress on wheel bearings. This can cause premature wear and lead to unusual noises.

7. Accidents or Collisions

Even a minor accident or curb impact can damage a wheel bearing. If a vehicle experiences a collision, it’s crucial to check the condition of the bearings afterward.

Symptoms of a Bad Wheel Bearing

Recognizing the early warning signs of wheel bearing failure can help you prevent costly repairs and potential accidents.

1. Humming or Growling Noise

A worn wheel bearing often produces a humming, growling, or rumbling noise that increases with speed. The noise may start faintly but gradually become more noticeable.

2. Noise Changes When Turning

If the noise gets louder when turning in one direction but decreases in the other, it’s a strong indicator of a failing wheel bearing.

- Noise louder when turning left? The right-side bearing may be bad.

- Noise louder when turning right? The left-side bearing may be bad.

3. Clicking or Grinding Sound

A grinding or clicking noise from the wheels suggests that the bearing’s internal components are wearing down. This type of noise often means the bearing is close to complete failure.

4. Uneven Tire Wear

Bad wheel bearings can cause improper wheel alignment, leading to uneven tire wear. If you notice excessive wear on one side of the tire, a failing bearing could be the culprit.

5. Vibrations in the Steering wheel bearing noise

As a wheel bearing deteriorates, it can create vibrations in the steering wheel, especially at higher speeds. These vibrations often worsen over time.

6. Loose Steering or Wheel Play

A faulty wheel bearing can cause the wheel to become loose, affecting steering responsiveness. If you lift the vehicle and shake the wheel at the 12 and 6 o’clock positions, excessive play suggests a bad bearing.

7. ABS Malfunction Light

Modern vehicles with ABS (Anti-lock Braking System) may display a warning light if the wheel bearing is failing. The ABS sensor is often integrated with the bearing, and any damage can trigger the warning light.

How to Diagnose Wheel Bearing

If you suspect a bad wheel bearing, follow these diagnostic steps to confirm the issue.

Step 1: Perform a Road Test

- Drive the vehicle at different speeds and listen for any unusual wheel bearing noise.

- Take note of whether the noise changes when turning.

Step 2: Jack Up the Vehicle

- Lift the suspect wheel using a jack and place the car on jack stands.

- Spin the wheel manually and listen for grinding or rough noises.

Step 3: Check for Wheel Play

- Hold the wheel at the 12 and 6 o’clock positions and shake it.

- If there’s excessive movement, the wheel bearing is likely worn out.

Step 4: Inspect for Leaking Grease

- Check the wheel hub for grease leaks.

- A broken seal may cause lubricant to escape, leading to bearing failure.

Step 5: Use a Mechanic’s Stethoscope

- A stethoscope can help pinpoint noise coming from the bearing.

- Compare the noise levels from different wheels.

How to Fix Wheel Bearing

If you determine that a wheel bearing is failing, the best solution is to replace it. Below are the steps to fix it:

Step 1: Gather Tools and Equipment

- Jack and jack stands

- Lug wrench

- Socket set

- Torque wrench

- Bearing puller or press (if required)

- New wheel bearing or hub assembly

- Safety gloves and eye protection

Step 2: Lift the Vehicle and Remove the Wheel

- Loosen the lug nuts before jacking up the car.

- Remove the wheel to access the wheel hub.

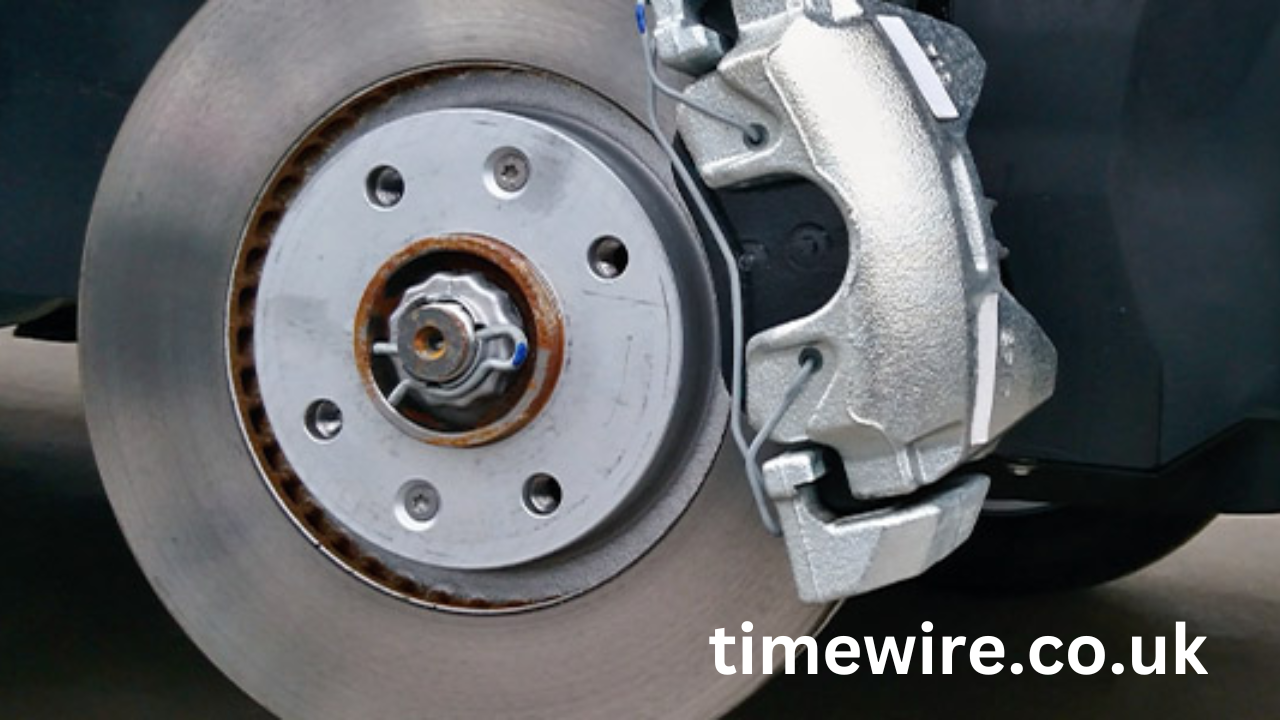

Step 3: Remove the Brake Components

- Take off the brake caliper and rotor.

- Secure the caliper with a zip tie to prevent strain on the brake line.

Step 4: Remove the Old Bearing

- If the vehicle has a hub assembly, unbolt and remove it.

- For pressed-in bearings, use a bearing puller or press.

Step 5: Install the New wheel bearing noise

- Align the new bearing properly before pressing it in.

- Ensure all bolts are torqued to the manufacturer’s specifications.

Step 6: Reassemble Everything

- Reinstall the brake rotor and caliper.

- Mount the wheel back onto the hub.

Step 7: Test Drive the Vehicle

- Take a test drive to check for any remaining noise.

- If the noise persists, recheck the installation.

Preventing Wheel Bearing Failure

To prolong the life of your wheel bearings, follow these preventive measures:

- Avoid Driving Through Deep Water or Mud – Moisture can damage the seals and lead to premature failure.

- Perform Regular Inspections – Check for noise, vibration, and wheel play at every tire rotation.

- Maintain Proper Tire Balance and Alignment – Misaligned wheels put extra stress on the bearings.

- Drive Cautiously Over Rough Roads – Avoid potholes and sudden impacts.

- Replace Bearings in Pairs – If one bearing fails, the opposite side may not be far behind.

Conclusion

Wheel bearing noise is a common issue that should never be ignored. A failing bearing can lead to serious safety concerns, including wheel detachment. By recognizing the symptoms early and following proper diagnostic and repair procedures, you can ensure a safe and smooth driving experience.

If you’re not comfortable replacing a wheel bearing yourself, it’s best to consult a professional mechanic. Regular maintenance and inspections will help you avoid costly repairs and keep your vehicle in top condition.